Getting The Best Set Screws For Your Needs

Before choosing the best set screw for your project, consider the following factors to ensure it meets your needs

We are dispatching same-day for all "in stock" items ordered before 2pm.

Your basket is currently empty.

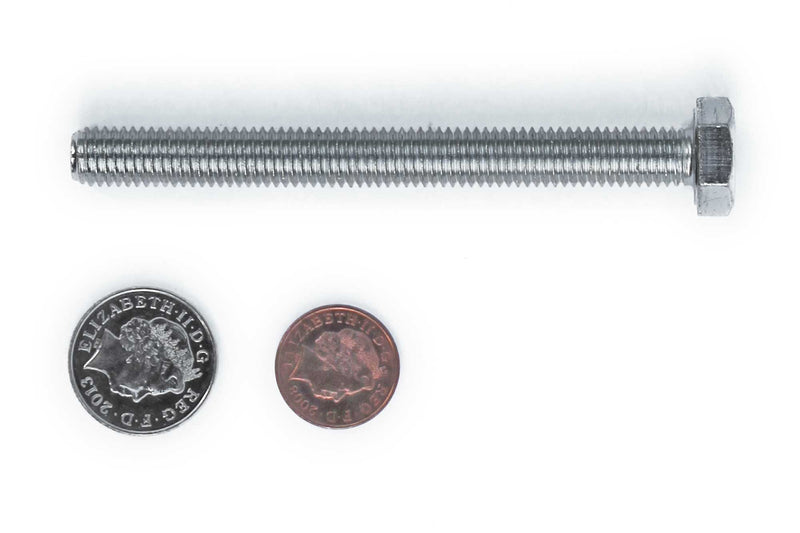

Set screws are typically used to fasten two objects together. They are threaded all the way to the head and are fully inserted into the receiving object. Set screws are suitable for use with metal and plastics, but ensure you review our specifications to be certain you are buying fixings suitable for your needs. Our hexagon set screw are recommended for use with our tarmac fixing nut.

Read more

Set screws (also sometimes called set pins, set bolts or grub screws) are important components in mechanical assemblies, securing one part to another without the need for a nut. Instead, the friction between the point of the set screw and the component holds it in place. Set screws don't typically protrude from the component being fastened because the entire screw fits into the threaded hole; this allows for a concealed fit.

Unlike standard screws and bolts, set screws are screwed into a pre-tapped hole. They come in a range of designs, like cup point, flat point and cone point set screws, each offering advantages for specific use cases. Because these screws are typically used within mechanical assemblies, they are usually made from strong materials like steel, stainless steel, or alloy steel, in order to be durable and reliable in different working conditions.

Before choosing the best set screw for your project, consider the following factors to ensure it meets your needs

Give our trained sales team a call on +44 (0)1905 794875, they will help you in choosing a suitable system for your needs and will also be happy to discuss discounts for bulk quantity requirements and special delivery need.

We have the full range shown above in stock on the shelf ready to ship out next day, we offer special delivery services and can even arrange same day delivery on many products.