Checkers Wheel Chocks For All Sizes Of Vehicles

Wheel Chocks For All Types Of Vehicle

Wheel chocks serve one key purpose, to keep any size of vehicle in place when parked, being worked on or not in use. They come in all sizes and for use with everything from small domestic cars all the way through to large HGVs and even mining equipment.

The crucial thing when purchasing wheel chocks is ensuring that you get the correct size, quantity and of course how to install them correctly.

A world leading manufacturer makes our range of wheel chocks, they are solid and will stand up to many years of use.

Important factors to consider when buying wheel chocks

- How heavy is the vehicle you are chocking

- How large are its wheels and tyres

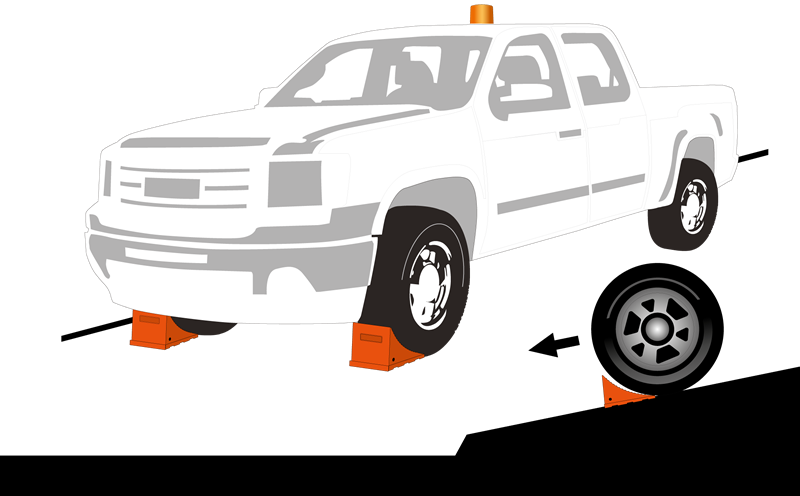

- Will you be chocking the vehicle on an incline

- What surface are you chocking the vehicle on

Weight

The weight of the vehicle being chocked will need to be the gross weight, that would include any load and fuel, etc.

Tyre Size

Tyre size needs to be measured as the diameter (from one side of the wheel to the other). This will ensure the wheel chock fits the radius of the tyre and is not too small.

Gradient

The incline you are chocking the vehicle on will have an effect on how many chocks you need; level surfaces need the wheels chocking either side. Where as inclines generally only need one side to be chocked.

Surface

The surface is less of an issue in the UK, but for countries where the ground is frozen for long periods, ice studs may be required for the chocks. Gravel and other loose materials will also affect the chock required.

Wheel Chock Size Guide

| Tire Diameter Gross Vehicle Weight | Up to 81.3cm Diameter (32") | Up to 88.9cm Diameter (35") | Up to 96.5cm Diameter (38") | Up to 116.8cm Diameter (46") | Up to 165.1cm Diameter (65") | Up to 241.3cm Diameter (95") | Up to 266.7cm Diameter (105") | Up to 360.7cm Diameter (142") | Up to 419.1cm Diameter (165") |

|---|---|---|---|---|---|---|---|---|---|

| Up to 13,608 kg (30,000 lb) | UC1700/ UC1400-4.5 | UC1700 | UC1500-4.5 | UC1500-4.5 | MC3009 | MC1210 | - | - | - |

| Up to 18,144 kg (40,000 lb) | UC1600/ UC1400-6 | UC1600 | UC1500-6 | UC1500-6 | MC3009 | MC1210 | MC3010 | - | - |

| Up to 33,680 kg (50,000 lb) | UC1400-6 | UC1500-4.5 | UC1500-6 | UC1500-6 | MC3009 | MC1210 | MC3010 | - | - |

| Up to 27,216 kg (60,000 lb) | UC1500-4.5/ UC1400-6 | UC1500-4.5 | UC1500-6/ AT3512 | UC1500-6/ AT3514 | MC3009 | MC1210 | MC3010 | - | - |

| Up to 31,751 kg (70,000 lb) | UC1500-6 | UC1500-6 | AT3512 | AT3514 | MC3009 | MC1210 | MC3010 | - | - |

| Up to 36,287 kg (80,000 lb) | AT3512 | AT3512 | AT3512 | AT3514 | MC3009 | MC1210 | MC3010 | - | - |

| Up to 68,039 kg (150,000 lb) | - | - | - | AT3514 | MC3009 | MC1210 | MC3010 | MC3012 | MC3011 |

| Up to 111,130 kg (245,000 lb) | - | - | - | MC3009 | MC3009 | MC1210 | MC3010 | MC3012 | MC3011 |

| Up to 166,015 kg (366,000 lb) | - | - | - | - | MC1210 | MC1210 | MC3010 | MC3012 | MC3011 |

| Up to 249,476 kg (550,000 lb) | - | - | - | - | MC3010 | MC3010 | MC3010 | MC3012 | MC3011 |

| Up to 387,821 kg (855,000 lb) | - | - | - | - | - | MC3012 | MC3012 | MC3012 | MC3011 |

| Up to 725,748 kg (1,600,000 lb) | - | - | - | - | - | MC3011 | MC3011 | MC3011 | MC3011 Min. 4 Req. |

| Up to 725,748 kg (30,000 lb) | - | - | - | - | - | - | MC3000 | MC3000 | MC3000 Only 2 Req. |

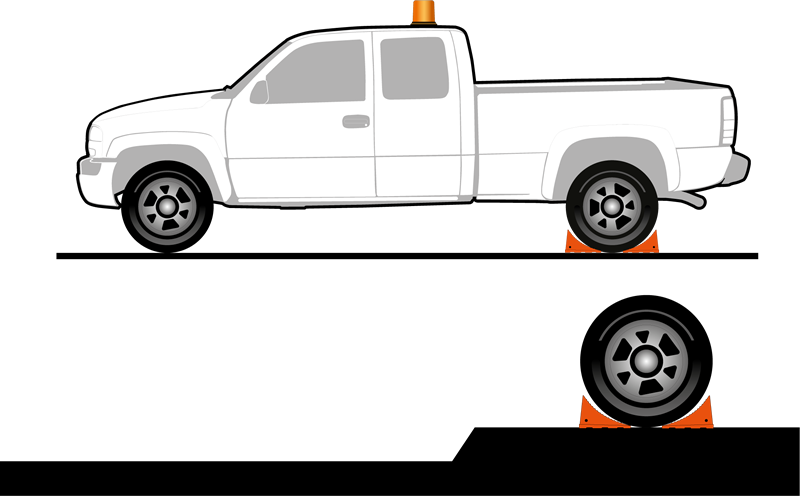

Proper Chocking of tyres

All wheel chocks should be placed in the centre of the tyre tread, not to the edges. By placing wheel chocks at the centre of the tyre, it is far harder for the vehicle to push the chock aside.

Any external forces applied to the vehicle should be taken into consideration. You may be loading the vehicle on an uphill gradient with chocks behind the wheels, but what if a forklift is likely to push the vehicle uphill. You will need chocks to counteract that force ensuring the vehicle does not move away from the loader.

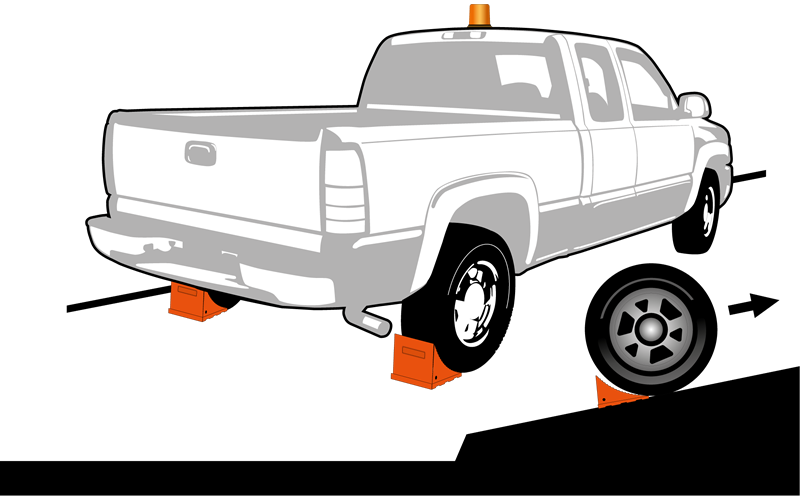

Using Wheel Chocks on Gradients

When chocking a vehicle, it is imperative that the gradient is taken into consideration. The gradient will have an effect on how many chocks are required to chock the vehicle safely.

Facing Downhill

In this instance, you will need to place the chocks in front of the front tyres on the downhill side.

Facing Uphill

When the vehicle is facing uphill, you will need to put the wheel chocks on the downhill side again, behind the rear tyres.

On a level surface

Wheel chocks should be placed either side of wheels when you are on the level or if you are unsure of the gradient. This will prevent the vehicle from moving in either direction.

Long Lasting and durable materials

The material our wheel chocks are made from makes them highly durable and resistant to contamination from fuel, oils, lubricants and other solvents. They will outlast wooden, aluminium and other materials.

Different From Parking Stops

If you are looking for parking stops you need to look in our parking stops section. You will find stops there for all sizes of vehicle, including coach stops, car stoppers and HGV wheel stoppers.

Further questions and information about wheel chocks.

If you have any questions about our range of wheel chocks, please call our sales team on +44 (0)1905 794875. They will be happy to discuss your wheel chock requirements and help you find the right chock for your needs.

SAFETY NOTE: All wheel chock tables and references including that given over the phone are as a guide only. Each instance of use will need to be surveyed individually to ensure the correct chock has been selected. We hold no responsibility if the incorrect wheel chock is chosen or misused.